Questions Answered by N. R. Woodward

Author of The Glass Insulator in America

Reprinted from "INSULATORS - Crown Jewels of the Wire", June 1973, page 2

William Davis of West Babylon, New York writes: I recently acquired an

insulator that I would like to inquire about. It is a CD 295 Hemingray 72, but

it is not embossed as shown in any of the reference books I have. It appears

to be a mold change from a No 4 high voltage.

The embossing on the front is as

shown for a No 4 H.V. -- HEMINGRAY / PATENTED MAY 2

1893

The embossing on the back is: HIGH VOLTAGE

/ MADE IN U.S.A. / No 72

I can discern some letters under

"MADE IN U.S.A.", and I'm positive this was struck over TRIPLE

PETTICOAT - some of the original letters were utilized in the change. Also the

number 4 is quite obvious under the 7 in 72.

I know that mold changes and strike overs are not that uncommon, but I would

like to know if this adds anything to the rarity of an insulator. One can't help

but wonder how many of this particular specimen were produced before one of the

known listed variations emerged. Thank you for any light you may be able to shed

on this.

- - - - -

In reply to William Davis: Your No. 72 with the traces of previous mold

engraving is interesting. That particular insulator went through several

changes; and evidently the molds weren't used continuously enough that they wore

out, so they were simply re-engraved and used over a long period of time. As I

have stated before, these remnants of previous engraving are most valuable in

that they prove beyond a doubt the order in which various numbers and lettering

arrangements were used. Beyond that, it would seem impractical to make a blanket

statement as to increased value due to this detail. If a sufficient number of

collectors were to specialize in these, their prices would no doubt Increase. As

of now I do not know of such a demand.

Question from Charles Bullock, Waukegan, Illinois: I would like to know if

you could supply me with any information on the following insulator. It is a

very light green H. G. Co. beehive. The embossing is what is so curious. There

is an A on the crown instead of an H. The front says H. G. CO., and the back has

PETTICOAT with an A under it Thanks.

- - - - -

In reply to Charles Bullock: The H. G. CO. / PETTICOAT series of CD #145 is

most interesting. This is the first of this style by Hemingray; and, although we

can't prove it in any way, it would seem to surely be Covington production. The

A is a mold letter. This series is found with letters A to N. Sometimes they

appear in one place on the insulator, sometimes in another, and sometimes (as

the one you have) they appear on both crown and skirt.

Your mention of this insulator gives me a chance to speak of one of my

favorite mold sets. What a fine "specialty" collection these would

make! First looking for all the molds, then looking for as many colors of each

as could be found, would go on forever and make a very colorful shelf. Evidently

cullet was used, as they came in all colors. And yet, with the exception of the

ambers and purples, they are not rare enough so that one would need to invest a

great deal in such a display.

Ed (???) writes: Have found four CD 115 Hemi 10, all light pink and all with

this design on top. Would like to know if any other readers have any like this,

also what they are worth.

- - - - -

The pink Hemingrays were made 1941-42. The "design" on the crown

wasn't intended, but is where the glass folded together in the bottom of the

mold during filling of the mold. These folds are created where the surface of

the glass begins to cool slightly. This group is rather common, and I know of no

particular value being attached to them.

Don Kenyon of San Dimas, California states: I have come across an insulator

which I hope you can give me some information on. It is a Whitall Tatum Co. No.

5, and, though the mfg. number is in Milholland's book, I cannot find the same

design in Milholland, Tibbits or Hill. I guess the closest to it in C. D. is

either C. D. 167 or 168. It must seem trivial to you with all your knowledge of

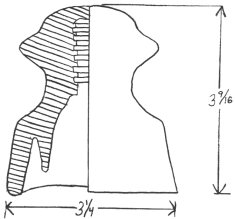

insulators, but please answer this for my curiosity. (sketch below)

- - - - -

In reply to Don Kenyon: The Whitall Tatum No. 5 shown is the CD #165.1. It

was previously listed as CD #165 along with the new style Hemingray - 20 (1941

and 1942 mold sets): but design of the crown is a bit different, and it has been

given its own number.

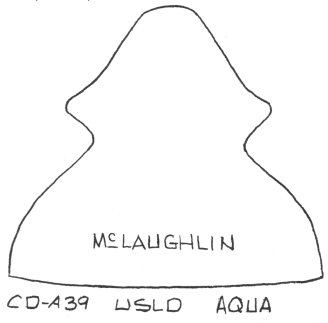

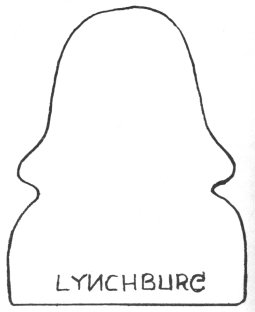

From Jerry Gibby: I have acquired two insulators recently, and I have no

info. on them. Maybe you can help shed some light on them, and maybe their

value. Thank you.

|

Same dimensions, but a pointed top. |

| LYNCHBURG - Note spelling and smooth base - Aqua.

Back - NO. 36 - U.S.A. |

|

- - - - -

In reply to Jerry Gibby: Nothing is known as to the USLD Insulators; and this

slight variation in crown formation probably had no significance.

According to the brochure prepared by Lynchburg Glass Corporation, insulators

were made with drip points unless the buyer requested a smooth base rim. In the

case of No. 36, quite a few buyers evidently did request the smooth base, as

they are fairly common. You did not list the mold number; but all of that number

in that mold set would have the backward N. This would be one-eighth of the

production during the time that mold was used, assuming it was an 8-mold press.

Mrs. J. P. Swift, Box 477, Gardnerville, Nevada 89410 has a question on

several insulators:

Insulator A - CD 102 - No Name - No embossing. Light aqua, tiny bubbles -

three piece mold - thick base - crude - large size measuring 2 5/16 wide - 3 3/4

tall - near mint. Threads are not long like the one identified as "D"

on page #39 in the OBM, September 1972 issue. It does not have wide mold seams.

Near mint.

Insulator B - CD 112 - No Name - No embossing. Light aqua, tiny bubbles -

three piece mold - thick glass - small spot of glass underside of dome just

above top of threads. This insulator appears to be identical to a CD 112 that I

have in my collection which is embossed S.T.B.& T.Co. I cannot tell them

apart except for the embossing. Near mint. Size 3 1/2" in height - 2

1/4" in width.

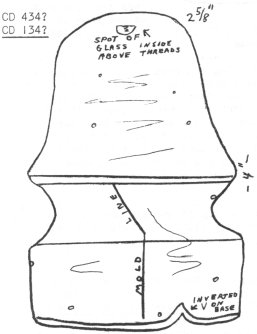

Insulator C - CD 434?? or CD 134?? (Sketched at left.) No Name - No

embossing. Light aqua, tiny bubbles three piece mold - small spot of glass

underside of dome just above top of threads. The mold lines seem to fall to the

left through the wire groove approximately a distance of 1/2 Inch. Small upside

down V on one half mold on the base making it appear to have a chip on it,

but it is where the glass did not meld correctly. Near mint. Size 4" in

height 2 5/8" in width.

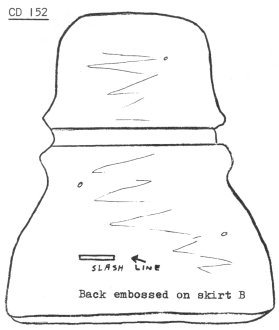

Insulator D - (Sketched on page following) - CD 152 Front B - Back 1/2

horizontal slash bar on skirt. Olive green - near mint. The "B" and

the "slash bar" are not centered on each half mold. They are about

one-third of the way over from one of the mold lines.

We so much enjoy each and every article in the Crown Jewels, and are

especially interested in the research articles. I know you are very busy, but I

am hoping some of your readers might also be interested in the above insulators.

Other collectors probably have at least one of them somewhere. We would be happy

to answer all correspondence from any of your readers.

The CD 152 I came across in an antique store in Nevada. The CD 102, 112 and

134 were bought in Alaska last July.

Are the small spots of glass unusual in insulators? Could you tell me if

these are unusual insulators; and does anyone know who made them, including the

CD 112 S.B.T.& T.Co.? I would appreciate any more information on any of them.

- - - - -

In reply to Mrs. J. P. Swift: The unmarked insulators with generally light

green bubbly glass are unidentified. I feel as you do, that beyond a doubt the

same glass works made the S.B.T.& T. CD #112, as it does exactly match the

unmarked ones. This association has led to speculation that the plant may have

been in one of the southern states in S.B.T.& T. territory. But there are two

or three other styles as well that seem to fit this same source; and they come

from all over. And you say that yours came from Alaska! It will be a miracle if

we ever get positive identification on these.

As to the points of glass at the top of the pin hole; these have no

significance and are where the mandrel was held in a chuck during machining.

Betty Lacey, University, Alabama writes: In reference to your reply to a

question from Elton and Lynda Gish of Port Neches, Texas on page 4 of the

January 1973 issue of Crown Jewels of the Wire, I believe I have some additional

information. This concerns the Brookfield mold set of extra heavy glass and

larger base diameter than is usual in Brookfield CD 145.

I have what I believe is a number 1 of this series. The heavy glass and

larger base are identical (I also own Nos. 2 and 4). The front is marked with a

B, the back with a 1, and there is a B on top of the crown. Just thought you

might like to know.

- - - - -

In reply to Betty Lacey: Thanks for reporting the "1" of this set.

Someone else has also reported one of these--so that makes a set of four. Are

there any others?

Paul Greaves of Carmichael, California states: I have two insulators I would

like your opinion on. One is a CD 208 Hemingray No 44 and the other is a CD 133

H. G. CO. / PAT. MAY 2, 1893 STANDARD. Both of these insulators are what I've

been told to be a "Peacock Blue". The two I have are both damaged on

the drip points. I have not been able to find this color variation in any books

I have. Can you give me some information on how rare (or common) these two are?

I also have a HEMINGRAY No 12, PAT. MAY 2, 1893 CD 113 in jade milk swirl. I

haven't seen the No 12 (in milk) at any shows, nor is it listed in my book. It

is a beautiful color and makes a good display piece for my window shelf. I would

sure appreciate any information you have.

- - - - -

In reply to Paul Greaves: The variations in shades of blue and aqua in the

Hemingray insulators are very difficult to describe and to reach a perfect

understanding with another collector. Since the CD #208 and #133 are not the

most common styles to begin with, I imagine an unusual variant in color would be

difficult to match and could be called "rare". However, whether this

would greatly increase their commercial value would depend on whether that

particular color appealed to a particular buyer.

The milky swirls in the common styles of Hemingrays are not too unusual, as

No. 9, 12, 16, 19, 20 and perhaps others. But they are attractive and would be

in demand far more than a plain aqua color.

Steven A. Wakefield writes: I'd like to thank Mike Cheuvront for sending in

the picture of the Brookfield signal. I think the picture makes a good case

for a new C. D. number. I have a theory which might explain the use of this

particular Brookfield. I found mine on a four-point transposition bracket. In

fact, the only ones I've seen were on a tramp. bracket. I think that the wire

groove ridge and "shelf" (above the groove) were designed to offset

the extra strain exerted on a 4-point tramp. insulator. The thicker shelf and

deeper groove also prevented the insulator from jumping its groove.

With the two Mike mentioned, that makes five I know of--all from the same

lead. I'd like to know if Mr. Woodward would be willing to assign a different C.

D. number for this insulator.

- - - - -

In reply to Steven Wakefield: As regards the Brookfield in question, It looks

as if it does need a new CD number (a decimal number); but I would have to see

the insulator itself first.

However, it wouldn't be designed for use on a point transposition such as

suggested. Point transposition brackets of this general style were first used on

Bell System carrier circuits in the late 1920's years after Brookfield went out

of business. These were used exclusively with CD #128 and other carrier

insulators. The modified style was used by the railroads and Western Union in

post World War II and when they were put up, whatever insulators were on the

arms were used, with ordinary Hemingray - 45 used as needed. No special

insulators were used with these.

From a mechanical standpoint, no special requirements are involved for point

transpositions, since the compression strength of glass is very great, and as

long as the insulator is properly mounted on the cob, it isn't under any

particular strain other than the lateral pressure of the wire. And so far as

needing an extra deep groove to hold the wire in place- -did you ever try to get

an insulator out of a transposition without removing the tension first from the

line?? 'Nuff said.

|